Every year, businesses waste millions of dollars in operating costs related to their forklifts and material handling. Toyota Material Handling Australia's telematics and forklift fleet management programmes can help you control and minimise operating costs, and combined with our national network of service technicians and parts experts, you can be assured that your forklift equipment will be operating at peak performance.

We understand that every company has specialised needs and the key to making successful decisions requires accurate and up to date information. Our forklift fleet management team can develop and implement pricing and auditing procedures to assure that you are receiving the most cost-effective, competitively priced package on an ongoing basis to help reduce your forklift operating costs and increase productivity.

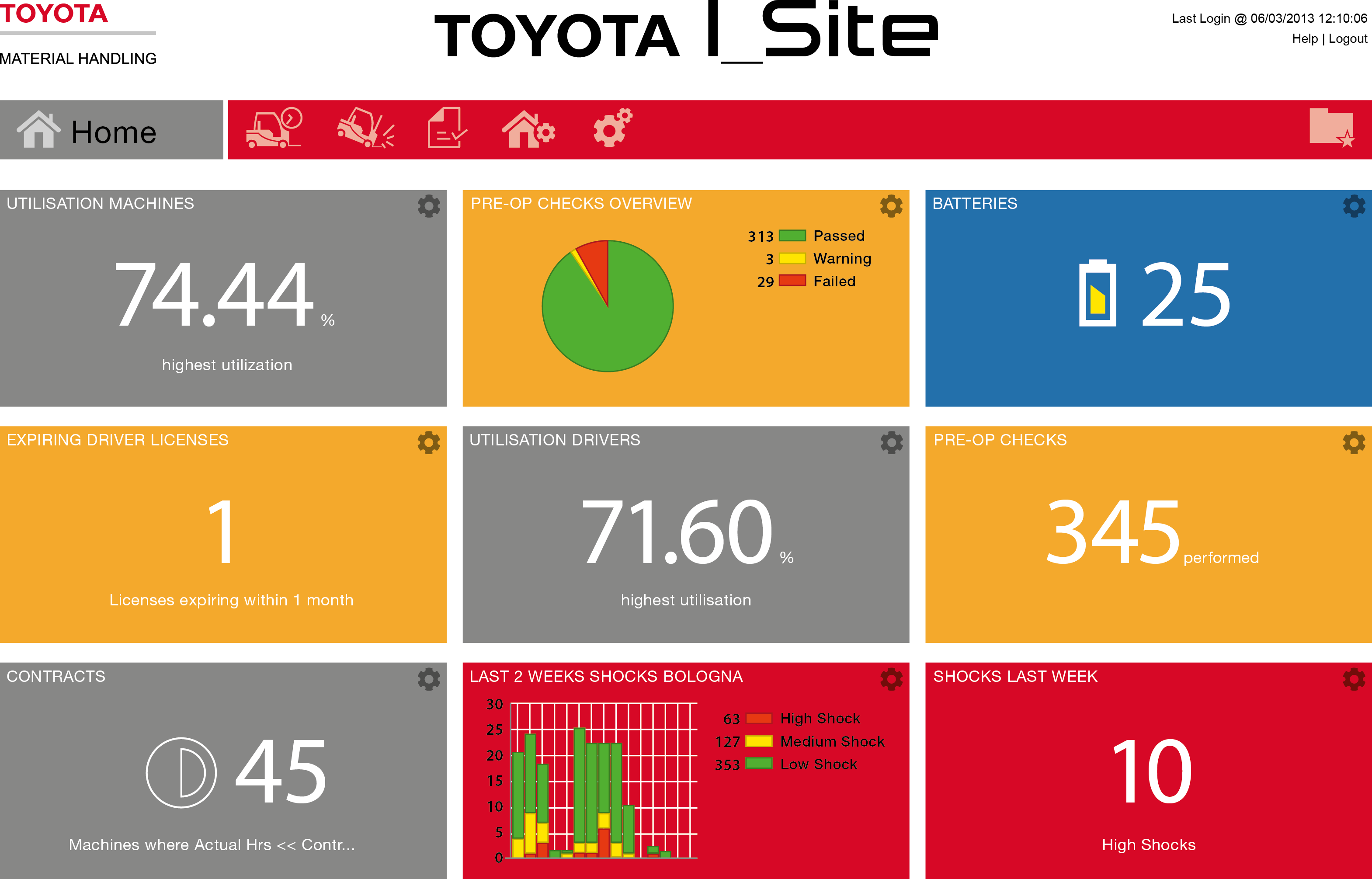

We also welcome the opportunity to explore ways in which we can help raise your company's operating efficiency and provide a no fuss, centralised account management platform. Our approach is based on an intelligent working partnership where we work with you to deliver tangible benefits over time and in the process help to optimise your forklift and materials handling operation.

Forklift Fleet Management